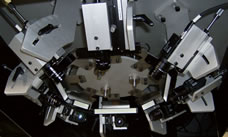

Vision sensors are low-cost, high-performance online inspection devices that are used to automatically measure parts, verify the correct assembly of products, identify parts, and guide production equipment. They can also be used in a variety of printing applications, from verifying print quality, location, and position to deciphering 1-D and 2-D barcodes.

Vision sensors help to reduce the human error element on the factory floor. They increase efficiency by providing real time production data for an SPC package to provide trending and warn/fail conditions.

In order to have a robust, 100 percent accurate inspection, it is critical that the installation have proper lighting, lenses, and professional programming. IES has dedicated itself to vision by making a long-term commitment to obtaining these results.

With a vision system from IES, manufacturing has a flexible tool that can improve productivity, ensure quality production of a part, increase efficiency, and lower production costs.