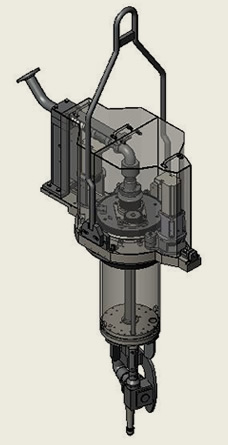

The RTC 1098 was originally developed to wash calcium carbonate from the inside of a railroad tank car but can be utilized to wash many other tanks and reservoirs as well. This unit automatically washes out the entire rail car in approximately 45 minutes while the operator is freed up to tend to other duties.

The unit utilizes two servo motors to produce a fully programmable and customizable wash pattern that can be adapted to most any size tank via the supplied touch panel. The touch panel is preprogrammed with operator friendly menus for selecting “light”, “medium”, “heavy”, or “custom” wash patterns.

The system is also fully customizable by the end user to accommodate changing conditions. Due to the caustic nature of calcium carbonate, the unit was designed and built using 304 stainless steel material. The unit utilizes a wash solution of water and calcium carbonate at approximately 225 gallons per minute at a pressure of 250 psi through an 11/16 orifice jet.