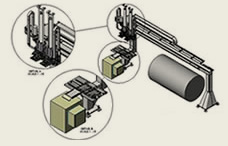

IES is experienced in the design and building of assembly, testing, processing, and production equipment utilizing your preferred components and specific company specifications. Our mechanical and electrical engineers have earned a reputation for building high quality, robust equipment for the manufacturing plant floor.

IES Inc. will work with you to design and build from an idea, will develop a concept from scratch, or take an existing concept and adapt it to specific need. We provide start-up assistance as well as equipment installation.